While passenger EV charging has entered a race toward “200 kilometers of range in five minutes,” the charging demands of heavy-duty commercial vehicles point to a far more transformative unit of power—the megawatt (MW). This shift is not merely about higher numbers on a specification sheet; it represents a critical enabler for the smooth, large-scale electrification of the transport industry and its business models.

At the center of this transition stands a foundational standard: the Megawatt Charging System (MCS).

What Is MCS?

MCS is not simply a higher-power extension of existing charging technologies. It is a comprehensive international standard developed under the leadership of CharIN (Charging Interface Initiative), a global alliance of leading vehicle manufacturers, charging infrastructure providers, and technology organizations.

Its core objective is to establish a unified, safe, and reliable “common language” for megawatt-level energy transfer.

A Leap in Technical Specifications

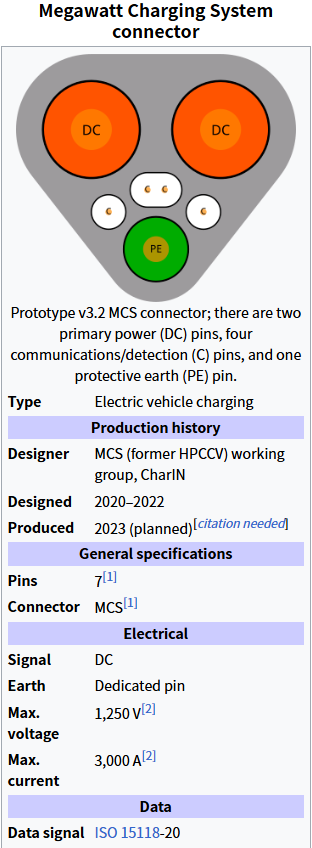

MCS defines performance thresholds well beyond those of today’s CCS (Combined Charging System) standard:

- Voltage: Up to 1250 V DC

- Current: Designed for up to 3000 A (with initial deployments typically targeting 1000–1500 A)

- Power: A theoretical maximum of 3.75 MW (1250 V × 3000 A)

In practice, pilot projects have already exceeded 1 MW, enabling electric trucks to gain more than 400 kilometers of range during a standard rest break.

Hardware and Safety Innovation

Megawatt-level charging generates substantial heat, making advanced thermal management essential. MCS connectors and cables therefore mandate liquid-cooling technology. This approach allows cables to remain relatively lightweight and flexible despite their power capacity, improving usability while ensuring thermal safety throughout the charging process.

The distinctive inverted-triangle connector design delivers enhanced mechanical stability and more precise communication contacts, further improving reliability at extreme power levels.

Future-Ready Communication and Compatibility

MCS is built upon—and extends—the ISO 15118 communication protocol, commonly associated with Plug & Charge functionality. This enables faster, more efficient vehicle-to-charger communication and advanced energy management.

A key design principle of MCS is partial compatibility with existing CCS standards. Many future vehicles are expected to feature both CCS and MCS inlets, allowing CCS charging for depot or overnight use and MCS ultra-fast charging for long-haul operations.

Why Is MCS Necessary?

The electrification of heavy-duty commercial vehicles presents challenges fundamentally different from those of passenger cars.

Massive Energy Demand and Battery Capacity

A fully loaded long-haul electric truck may carry a battery pack of 600–1000 kWh—six to ten times that of a typical passenger EV. Using today’s mainstream 350–400 kW chargers, full charging can take several hours, resulting in unacceptable downtime for commercial operations.

Strict Operational Time Windows

In the European Union, for example, regulations require truck drivers to take a mandatory 45-minute rest after every 4.5 hours of driving. An effective charging solution must deliver enough energy within this legally defined break to support the next driving segment.

The Payload Weight Trade-Off

Batteries are heavy. Increasing battery capacity to extend range directly reduces allowable payload, impacting vehicle economics and operational profitability.

The solution, therefore, lies not in endlessly scaling battery size, but in maximizing charging speed. MCS is designed to enable electric trucks to replenish hundreds of kilometers of range within 30–45 minutes—integrating charging seamlessly into existing transport rhythms rather than disrupting them.

Where Can MCS Be Applied?

Although MCS is primarily driven by the needs of heavy-duty road transport—such as trucks and coaches—its high-power, standardized design makes it well suited for other forms of heavy mobile equipment:

- Ports and Mining: Electric mining trucks, port AGVs, and heavy handling equipment

- Maritime Transport: Inland and near-shore electric ferries and work vessels

- Aviation: eVTOL aircraft and future regional electric aviation platforms

In essence, MCS lays down a standardized “energy highway” for any mobile application requiring rapid delivery of massive amounts of power.

(Image Source: CharIN)

INJET New Energy’s Strategic Approach

Recognizing the clear trajectory of charging technology, INJET New Energy has proactively integrated MCS compatibility into the core development roadmap of its next-generation high-power charging solutions.

Our modular megawatt power stacks are being engineered with MCS readiness in mind:

- Future-Oriented Interface Compatibility: Next-generation power stacks will support MCS charging interfaces, ensuring seamless integration with future mainstream heavy-duty electric vehicles.

- Scalable Power Architecture: The current design supports up to 1500 A output per terminal, with a clearly defined upgrade path toward 3000 A—protecting long-term customer investment and enabling smooth capacity expansion.

Conclusion

The electrification of heavy transport is a marathon, not a sprint—and charging infrastructure must lead the way. By aligning early with MCS, a globally recognized consensus standard, INJET New Energy aims to deliver solutions that meet today’s operational needs while remaining fully prepared for the megawatt charging era ahead.

For fleet operators and charging network developers worldwide, this means infrastructure that is not only reliable now, but confidently future-proof.