Injet finds that as electric vehicles (EVs) become increasingly prevalent, the demand for efficient and reliable charging infrastructure is paramount. DC charging stations play a crucial role in facilitating rapid charging for EVs, but the presence of a power controller within these stations can significantly enhance their functionality and maintenance procedures.

What is DC Charging controller?

A DC charging controller is the brain behind a DC fast charging station. It's responsible for managing the entire charging process, from communication with the vehicle to controlling the power flow.

Key Functions of a DC Charging Controller:

Communication: Acts as the interface between the charging station and the electric vehicle, exchanging data and commands.

Power Control: Regulates the amount of power delivered to the vehicle's battery, ensuring safe and efficient charging.

Safety Monitoring: Monitors various parameters such as voltage, current, and temperature to prevent faults and protect the vehicle and charging station.

Charging Process Management: Controls the different charging phases, including pre-charging, main charging, and post-charging.

Payment and Authorization: Handles payment transactions and user authentication.

What is the impact with or without a DC Charging Controller:

With Power Controller:

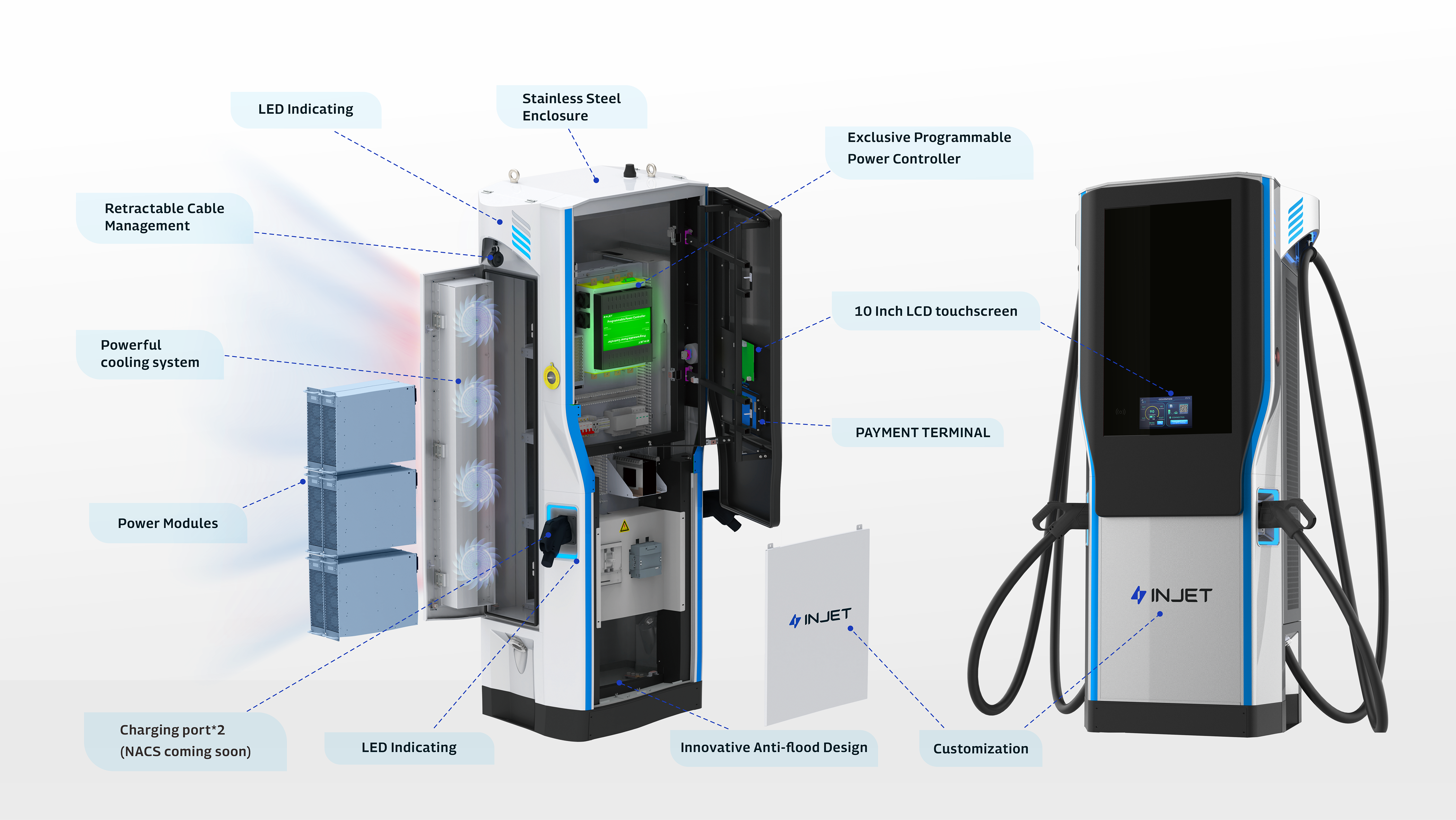

1. Programmable Power Controller (exclusive from INJET): This component acts as the brain of the charging station, allowing for precise control and regulation of power flow to the EV.

2. Integrated Smart HMI: Human-Machine Interface (HMI) provides a user-friendly interface for both operators and EV owners to monitor and control the charging process efficiently.

3. Charging Module: The core unit responsible for converting AC power from the grid to DC power suitable for charging EV batteries.

4. Cabinet: Housing for all the electrical components, providing protection and organization.

5. Cable & Plug: Essential for connecting the charging station to the EV for power transfer.

Without Power Controller:

1. DC Watt-hour Meter: Measures the amount of electrical energy consumed by the EV during charging.

2. Voltage Detection Transmitter: Monitors voltage levels to ensure safe charging operations.

3. Insulation Detector: Detects any insulation faults within the charging system to prevent electrical hazards.

4. Charging Pile Controller: Manages charging protocols and communication between the station and the EV.

5. Other Electrical Components: Including various power supplies, circuit breakers, relays, surge protectors, and wiring for electrical connections.

(Components of DC charging station with& without power controller)

Impact of Maintenance with or without a DC Charging Controller

With Power Controller:

Maintenance of a DC charging station equipped with a power controller is streamlined and efficient, typically requiring less than 8 hours to resolve issues.

1. Fault Diagnosis: Automated background systems quickly identify faults, reducing diagnosis time to 2-4 hours.

2. Component Replacement: If necessary, the power controller can be directly replaced within 2-4 hours, minimizing downtime.

Without Power Controller:

Traditional maintenance procedures for DC charging stations lacking a power controller can be time-consuming, taking anywhere from 2 to 10 days to resolve issues.

1. On-site Inspection: Maintenance personnel must physically inspect the station, taking 1-2 days to locate the fault.

2. Part Replacement: Once the fault is identified, obtaining and replacing the necessary components can take 2-6 days, depending on availability.

3. Repair and Recovery: Finally, 1-2 days are needed to repair the station and return it to operational status.

Embarking on a forward-looking journey towards sustainability and efficiency, Injet New Energy proudly presents its latest breakthrough – the Ampax Series DC Charging Station. This groundbreaking innovation heralds a new era in electric vehicle (EV) charging, promising a monumental shift in sustainable transportation technology.

The Ampax Series stands out with its cutting-edge features, setting a new standard for EV charging solutions. Central to its design is the INJET Integrated DC Charging Technology, featuring the exclusive INJET Programmable Power Controller. This pioneering technology ensures precise power management, delivering an optimal charging experience tailored to each EV owner's needs. But the innovation doesn't end there – the streamlined assembly process enhances production efficiency, pushing the boundaries of what's possible in EV charging infrastructure.