What do you need to consider if you are going to buy an electric car?

The following questions will come to your mind.

Are public charging stations expensive to use?

Can I install a charging station by myself?

What is the internal structure of charging stations?

ls it safe to use?

Do all electric cars use the same type of charging stations?

ls the charging speed sufficient?

ls charging convenient?

Are there many charging stations available?

In the end, the key question lies in the charging piles.

To figure this out, Jeremy reached out to us. We invited Jeremy, a reporter from ChengduPlus, to visit Injet New Energy's charging post production factory to interview and experience the charging post assembly process first hand.

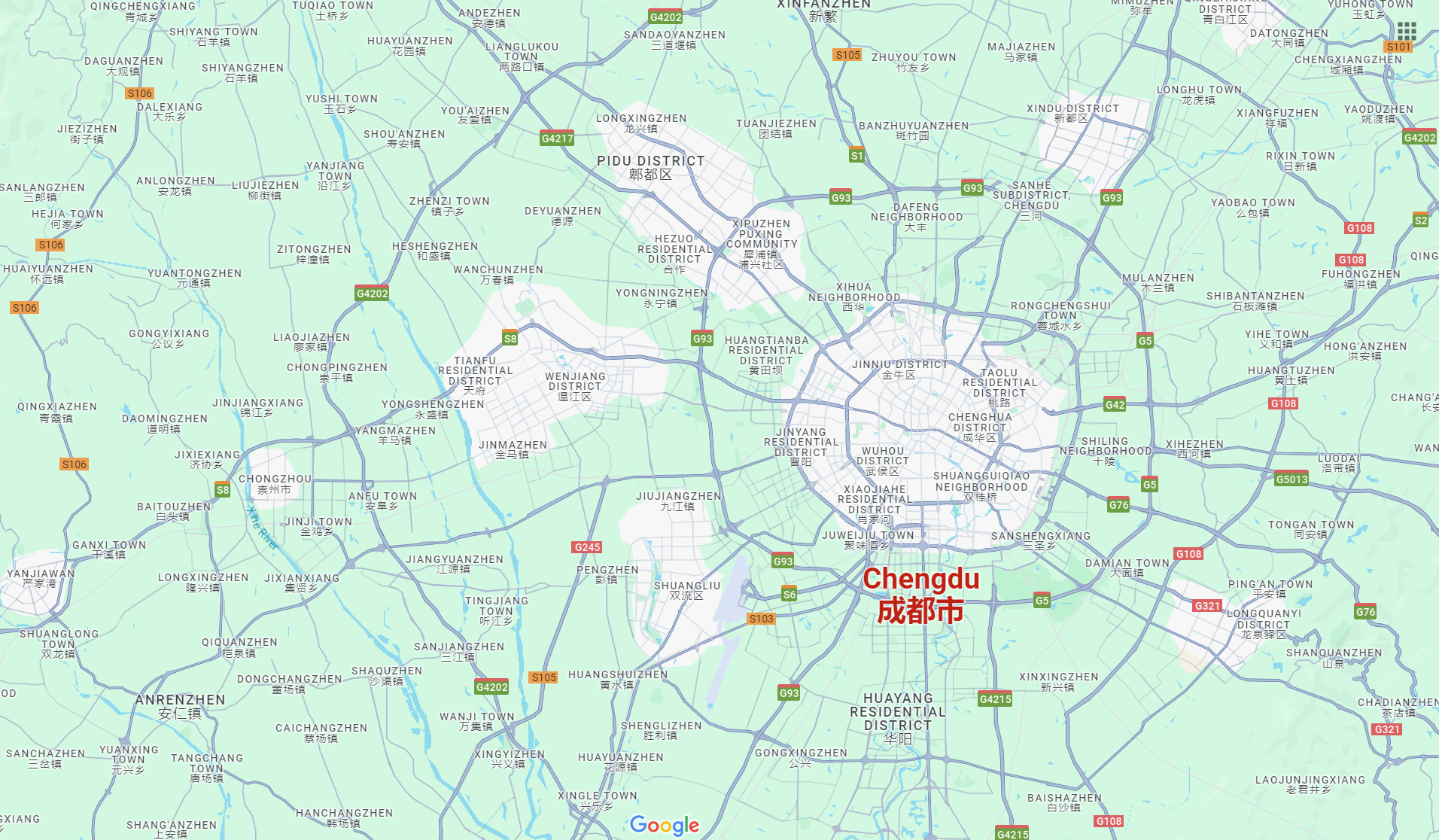

Injet New Energy - a manufacturing factory that is capable of producing 400,000 AC charger (Alternating Current) and 12,000 DC charger (Direct Current). What does 400,000 charging piles mean? Chengdu is a mega-city in Southwest China with a residential population of 20 million and 500,000 electric vehicles. So far, a total of 134,000 charging piles have been installed and put into use in Chengdu. That means if the factory is producing at full-capacity, they can actually produce the charging piles in the entire city of Chengdu within just 4 months!

Jeremy visited our EV charger production line and experienced the assembly process of AC EV charger. Injet New Energy has a very standard set of assembly processes. First entered the dust-free workshop. The assembly process is divided into six steps.

1.The first step, we check the shell, apply waterproof sealing tape, and attach the nameplate.

2.Our second station, we inspect the previous work, add our wiring and boards, and then pass it on to the next station.

3.The third step, mainly involving the installation of charging cables and the fitting of its leakage protection sensor, once the cables are securely connected.

4.The next station mainly involves connecting the charging cable,positioning the leakage protection device.

5.And the last station, primarily for organizing and locating the cables and attaching the panel.

6.The final step is the self-inspection by quality control. Once there’s problem, we will put them into different sections accordingly.

And then its done. Our charging piles undergo various tests during the development stage, such as high and low-temperature tests, pressure resistance tests, and salt spray tests. All the products of Injet New Energy have passed the relevant national certification standards, which guarantees the safety and quality of the products. CE is a mandatory European Union standard,representing strict safety requirements. You must have CE certification if you want to export your goods to EU countries. Some countries also require RoHS and REACH certification. Our products are exported to Europe and North America, such as Canada and the United States. For Canada and the United States, UL certification is required for the products to go there. Before each charging pile leaves the factory, we conduct aging and testing.

Currently, the ratio of charging piles to electric vehicles in China is 6.8,while in Europe, its 15 to 20. The development of overseas charging infrastructure lags behind the growth of electric vehicles, indicating significant market potential. Chinese-manufactured charging piles are not only for domestic use but also for extensive exports. According to data from Alibaba International,in 2022, opportunities for overseas sales of new energy vehicle charging piles grew rapidly by 245%. Over the next 10 years, the overseas demand for charging piles is expected to triple,with a market size of 15.4 billion euros (approximately 113.2 billion RMB). And buyers mainly come from Europe and America.