In our previous article, we discussed employee home charging.

When charging takes place at an employee’s home, it may appear to be nothing more than “residential electricity use.” In reality, however, companies are confronted with a much broader set of challenges—cost allocation, asset ownership, data visibility, and long-term operational responsibility.

The conclusion was clear:

Employee home charging is neither an upgraded version of residential charging nor a downsized form of commercial charging. It is a distinct corporate management scenario that must be designed independently.

Once companies reach this understanding, a natural assumption often follows:

Surely charging in the company’s own parking lot should be simpler.

In practice, the opposite is often true. Corporate parking facilities tend to be the place where electrification issues surface earlier—and where design mistakes are the hardest to undo.

(Image Source: ev connect)

Installing Chargers in Corporate Parking Lots: The First Challenge Is Not Technology

When employee home charging and corporate parking charging are viewed together, one common reality emerges:

Regardless of where charging happens, companies are rarely concerned with whether vehicles can charge. What truly matters is:

- 1)Will charging disrupt normal vehicle operations?

- 2)Is the system stable and controllable?

- 3)How quickly can service be restored if something goes wrong?

- 4)Can the system scale long term without requiring a full redesign?

This is precisely where corporate parking projects are often approached with the wrong design logic:

- 1)Employee home charging is treated as a purely residential scenario

- 2)Corporate parking is treated as an “internal version” of a public charging station

Yet a corporate parking lot is not a revenue-generating public site. It is an internal energy and fleet operations node, tightly coupled with daily business continuity.

(Image Source: ev connect)

For Enterprises, Compliance Is the Baseline—Efficiency Is the Differentiator

In the French market, compliance with NFC 15-100 is a prerequisite for any installation. But for enterprises, regulatory compliance alone does not create value—it is simply non-negotiable.

What truly affects project efficiency is whether installation is complex, error-prone, and difficult to replicate at scale. In real-world deployments, companies are far more concerned with questions such as:

- 1)Are additional protection modules required?

- 2)Will electricians need repeated coordination and parameter tuning?

- 3)Will installation timelines be extended?

This is why a core principle of enterprise-grade AC charging solutions is to absorb complexity inside the device itself, while remaining fully compliant with regulations.

For example:

- 1)Can the MID-certified meter be integrated into the charger rather than installed externally?

- 2)Can DC 6 mA residual current protection be built in instead of added as a separate module?

- 3)In large-scale rollouts, can offline network configuration be avoided to reduce deployment workload?

These design choices may seem subtle, but they directly determine the effort required when deploying dozens—or hundreds—of chargers at once.

What Corporate Fleets Really Care About: What Happens When Something Goes Wrong

From a fleet operator’s perspective, the most unacceptable scenario is not the occasional fault—it is extended system downtime after a fault occurs.

With traditional AC chargers, a hardware failure often means waiting for a technician to arrive on site, followed by removal and off-site inspection. During this period, the charger remains unavailable, and recovery time is unpredictable—posing a significant operational risk for fleet environments.

The value of a split-type architecture is not merely structural. It fundamentally changes the maintenance model—from waiting for someone to fix it to being able to replace it independently.

In real operations, the process can be straightforward:

1.The backend system remotely determines whether the issue is hardware-related

2.Once confirmed, the faulty unit is shipped to INJET’s distributor in France

3.The distributor sends a temporary replacement unit by courier

4.The enterprise performs the on-site replacement independently

5.After repair, the original unit is reinstalled

Throughout this process, the charging system does not remain offline for extended periods. With a single training session during initial deployment, enterprises can master the replacement procedure. In practice, the task is closer to changing a light fixture than repairing complex equipment.

For fleet operators, recoverability often matters more than the unrealistic goal of zero failures. Moreover, the cost of on-site service visits far exceeds that of standard logistics.

Stability Is Not Just Hardware—It Is the Ability to Evolve

Corporate electrification is not a one-time project. It is a multi-year transition. The greatest risk is not limited functionality today, but systems that cannot evolve tomorrow.

A Linux-based system architecture ensures that chargers are no longer “fixed at factory delivery.” Through remote firmware updates, enterprises can:

- 1)Upgrade chargers across an entire fleet simultaneously

- 2)Resolve issues without on-site intervention

- 3)Adapt functionality as enterprise platforms and systems evolve

For example, a system can be upgraded from full OCPP 1.6J functionality to OCPP 2.0.1, enabling future platform migration or deeper system integration.

The Inescapable Constraint of Corporate Parking: Grid Capacity

At the most practical level, corporate parking projects are constrained by grid capacity. Many companies are not unwilling to deploy chargers; their existing electrical infrastructure simply cannot support all chargers operating at full power simultaneously.

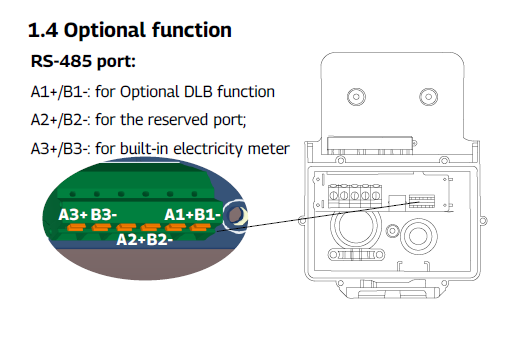

INJET’s solution connects multiple chargers into a unified system via RS-485, enabling intelligent power sharing:

- 1)Power is allocated within existing grid capacity

- 2)Distribution adjusts dynamically based on real-time demand

- 3)Overloads and tripping are avoided

The key advantage of this approach is that it requires no additional hardware and no costly grid upgrades.

Conclusion

Looking at today’s market, most AC chargers are designed either for public charging operations or for private residential use. The corporate fleet itself is rarely treated as an independent design premise.

The true complexity of enterprise electrification is not whether chargers exist, but whether—over time, at scale, and across long operational cycles—those chargers remain stable, controllable, and free from becoming operational constraints.

It is from this perspective that INJET has re-evaluated corporate fleet charging requirements and consolidated the corresponding design logic and deployment practices into a comprehensive AC charging solution for corporate fleets.

Download the full solution overview via the link below:

https://www.injetenergy.com/uploads/Injet-Swift-2.0-AC-Charging-Solution-for-Corporate-Fleets.pdf